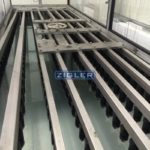

Description

This device allows you to control the tightness of can sealing during the automatic production cycle. Cans filled with product and propellant are water-tested. Proper water temperature (approx. 55 °C) allows the detection of any leaks.

Specifications

Diameter of supported cans: ø 35÷ ø 66 mm

Height of supported cans: 105 mm ÷ 320 mm

Valve type: aerosol valve with a diameter of 1″ without adapter

Capacity: 60 – 250 pcs/min. (depending on the version), i. e. each can is immersed in a water bath for at least 180 sec.

Cans guiding: plastic clips holding the container inside the aerosol valve

Leakage detection: leakage detection: visual – watching bubbles arising or by using infrared sensors

Power type: Electrical and Pneumatic

Supply voltage requirement: 3×400 VAC, 50Hz

Power input: 1kW (without heating system)

Required air pressure: 2 – 8 bar (0.2 – 0.8 MPa)

Air consumption: Max. 75 m3/h (can drying system)

Overall dimensions:

- Overall length: 5150 mm

- Overall width: 1460 mm

- Overall height: 1600 mm

- Volume: ~2,0 m3