Application

The ion exchange system IONTEC softens water used for beer and beer-based mixed drinks or for steam generation. Water hardness causes scale deposits in piping and process systems.

Description

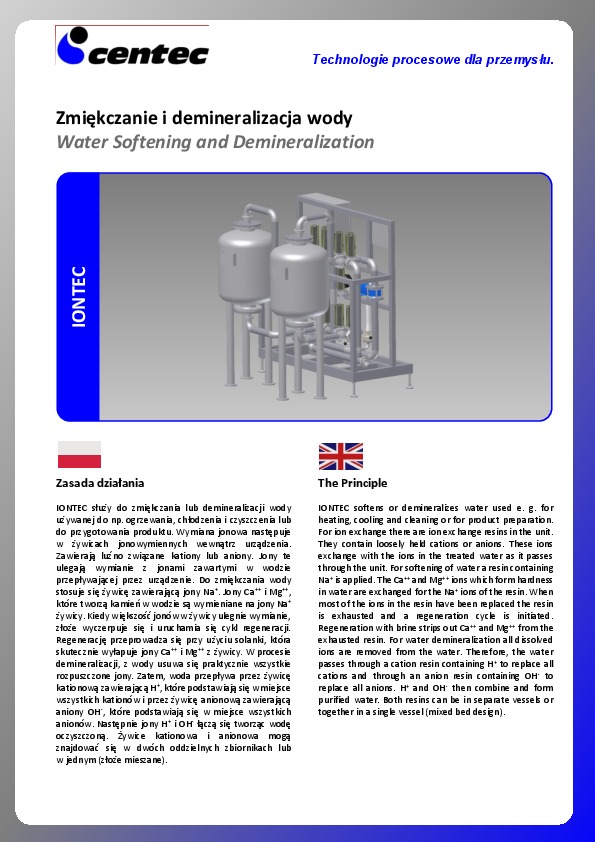

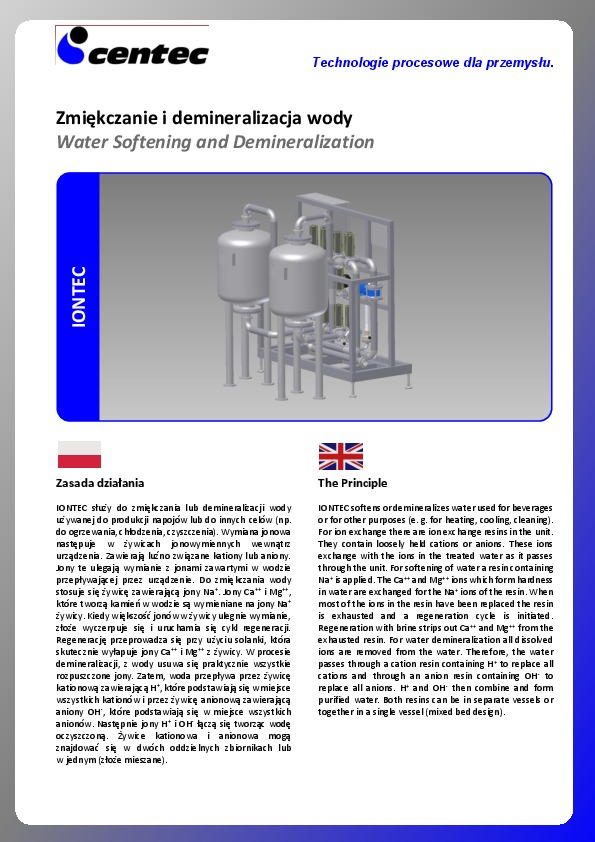

For ion exchange there are ion exchange resins in the unit. These resins are insoluble granular polymers appropriate for the specific application. In their molecular structure they contain loosely held positive cations or negative anions. These ions exchange with the ions in the treated water as it passes through the unit.

For softening of water a cation resin containing Na+ is applied. The calcium and magnesium ions which form hardness in water, creating scale deposits, are exchanged for the sodium ions of the resin. The resin binds more strongly with Ca2+ and Mg2+ than with Na+. When most of the ions in the resin have been replaced the resin is exhausted and a regeneration cycle is initiated. Regeneration with brine strips out Ca2+ and Mg2+ from the exhausted resin.

For water demineralization basically all dissolved ions are removed from the water. Therefore, the water passes through a cation resin containing H+ to replace all cations and through an anion resin containing OH– to replace all anions. The H+ and OH– then combine and form purified water. For regeneration the cation resin is treated with an acid. The anion resin is regenerated with a strong base. Cation and anion resin can be in separate vessels or together in a single vessel (mixed bed design). Systems for ion exchange are often used as the initial steps in a more complex water purification regime.

- All stainless steel execution as standard

- Mixed bed design on demand for water demineralization

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 – 3.000 hl/h |

| Material | according to requirements (plastics, stainless steel) |

| Options | different automation levels; duplex operation; remote maintenance access; hardness measurement; pre-filtration; Cleaning-in-Place |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl