- Virtually maintenance free liquid nitrogen dosing system for high speed lines.

- Discrete dosing for speeds up to 75.000 bottles/hour and 120.000 cans/hour, continuous flow for higher speeds

- Precision metering during steady stream without nozzle changes

- LN2-supply at max 7 bars = Suitable for typical bulk tank supply without need for dedicated phase separator

- Dosing accuracy : 1%

- Minimum dosing valve opening time of 5ms for easy adjustability of dosed quantity at all line speeds.

- Exceptional long-life servo actuator

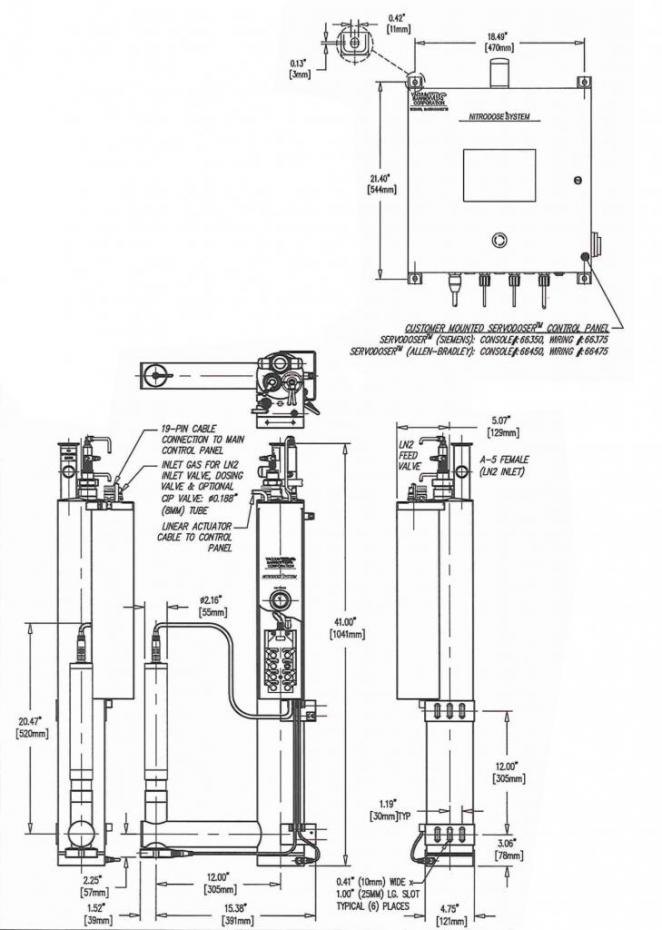

Specifications

Base unit including :

- Fully vacuum jacketed, stainless steel dosing unit. Electronic level controller with pneumatic inlet valve. Dosing arm with electrical high speed valve. Safety relief valve.

- Heated nozzle area and gas vent

- Integrated self generating nozzle purge system. No dedicated nitrogen gas supply required.

- Quick purge/ Quick warm up

- Pressure regulator for compressed air or nitrogen gas for pneumatic inlet valve actuation.

- Waterproof electrical junction box with stainless steel cover and integrated LN2 feed pressure gauge.

- Remote Siemens S7-1200 control panel with Color Siemens KTP600, 6” touch screen HMI (230V/50Hz or 115V/60Hz) in stainless steel NEMA 4x rated housing and alarm beacon.

or alternatively

- Allen Bradley AB1400 control panel with Color AB Panelview Component 600, 6” touch screen HMI (230V/50Hz or 115V/60Hz) in stainless steel NEMA 4x rated housing and alarm beacon.

- 6 meter electrical cables. 15 meter cable sets are optionally available.

- Advanced Self diagnostics logics with standard 2 alarm relay outputs (Profibus optionally available)

- Encoder ready

- Speed- and dose compensation capabilities

- 5 recipe storage

- Advanced graphical user interface with doser pictograms and self diagnostics

- Speed sensor (proximity).

- Infrared sensor for bottle detection (Dosing enabled only when container is present)

- Available languages for HMI and operation manuals : English, German, French, Spanish, Italian

- Complete operation- and service manual

Options

- Additional LN2 feed line : standard length is 3 meters from tank to doser. Any additional meter should be ordered in this option. Bayonet couplings will be needed in case of lengths longer than 12 meters.

- A standard 6 meter cables set from the doser to the PLC is included. Instead, a 15 meter set can be ordered optionally.

- Profibus communication utility between doser and filler

- Encoder with 10 m cable & shaft coupling (bracket not included). Shaft coupling for 10mm shaft sizes. Amount of containers/revolution to be specified.

- Additional languages for HMI and operation manuals upon request. The following languages are standard : English, German, French, Spanish, Italian.

Specialties

- For an overview of the different dosing head lay-outs, please click here

- LDV (Low Dose Velocity) heater block e.g. for hot fill applications (P/N : 56882)

- CIP heater block: automatic nozzle protection (P/N : 52850)

- The HF-LDV (Hot Fill-Low Dose Velocity) Heater Block (P/N : 61137)

- Combi LDV/CIP heater block: combines both benefits of the LDV and CIP heater block (P/N : 55300)

Installation

- Stainless steel (height adjustable) support in AISI 304 material (also available in AISI 316 on request). This support can be either on a 2×2 pod or a bottom plate basis.