Zigler Poland offers also aerosol filling devices for cans with a diameter of 22 mm and 25 mm. These “special” types of aerosol products are now very popular in chemical and pharmaceutical industry.

We offer both semi-automatic devices as well as fully automatic production lines for this type of aerosol products.

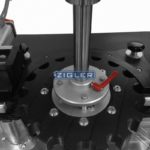

1. Semi-automatic line in “micro” version with very high accuracy and dispensing speed both for the product and the propellant. Devices in this version can be distinguished by minimum consumption of compressed air. They have small dimensions. Semi-automatic line capacity: up to 1,000 pcs/h.

2. Specially integrated machines with a capacity of up to 3,600 pcs/h for cans with a diameter of 22 mm or 25 mm and a capacity of up to 30 ml.

The standard automatic line has the following configuration:

- Infeed table – rotary or made of conveyor belts

- Automatic Rotary Module equipped with:

- Product dispenser (1-4 pcs)

- Valve inserting module

- Valve crimping device

- Propellant dispenser (1-2 pcs)

4. Valve elevator

5. Labeller (optional)

6. Rotary receiving table

7. Cans transport system between modules

8. Central control cabinet

3. Automatic line with configuration listed above can by modified to achieve a capacity of up to 6,000 pcs/h.

Zigler’s offer includes also a “special” version of the line for pharmaceutical products made in accordance with GMP standards.