Controls

- Allows for adjustments of dose amount and timing during operation

- Automatic line speed synchronization

- No container/no dose function

- NEMA Stainless Steel 4X PLC control panel

- Lighted touchpad controls for ease of operation

- Available in a variety of language formats

- Single dose capability for lab testing

- All equipment has NEMA quick connects

- Continually displayed current production rate

- Valve cycle counter with automatic notification at service intervals

- Allen Bradley or Siemens PLC controls

- Dose compensation logic for consistent results over a wide variation of line speeds

- Construction features

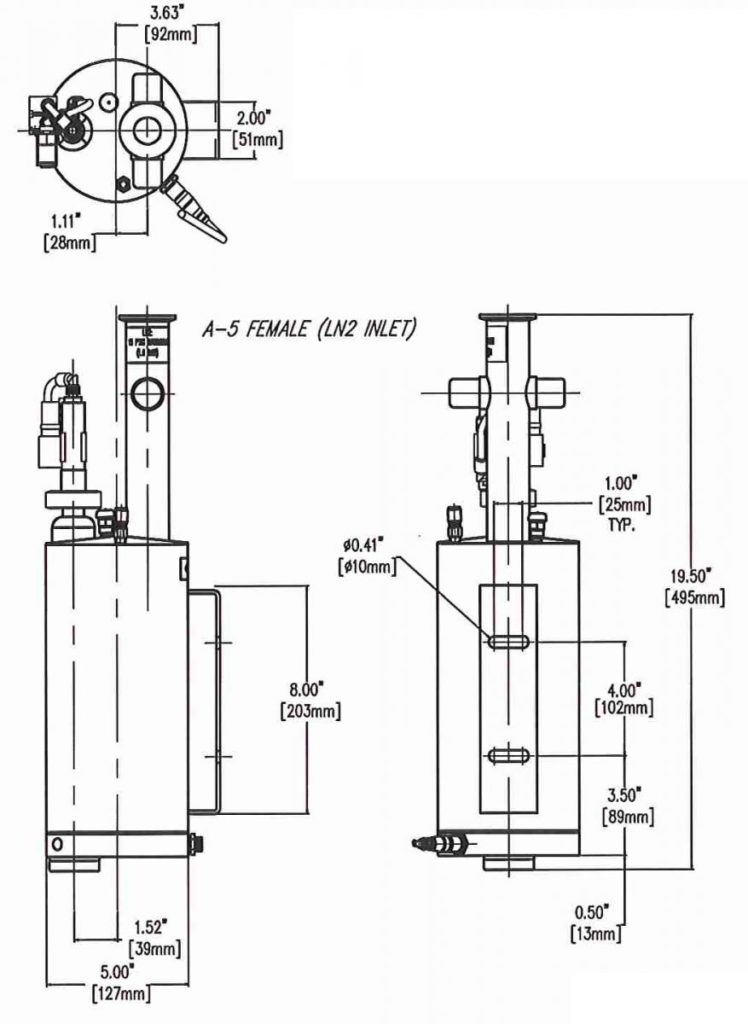

- Slim profile and simple mounting adapts to any filling line

- Designed to run off portable Dewars or connect directly with Vacuum Barrier’s LN2 piping systems Safety and Cleanliness

- 2-micron inlet filter to protect from foreign particles

- Nozzle and all hardware is safely captivated

- High efficiency – lowest LN2 consumption

- Built in pressure relief valves

- Totally frost-free operation

- Fully CE compliant

Options

- Additional LN2 feed line : standard length is 3 meters from tank to doser. Any additional meter should be ordered in this option. Bayonet couplings will be needed in case of lengths longer than 12 meters.

- A standard 6 meter cables set from the doser to the PLC is included. Instead, a 15 meter set can be ordered optionally.

- Additional languages for HMI and operation manuals upon request. The following languages are standard : English, German, French, Spanish, Italian.

Installation

- Stainless steel (height adjustable) support in AISI 304 material (also available in AISI 316 on request).

- This support can be either on a 2×2 pod or a bottom plate basis.