Application

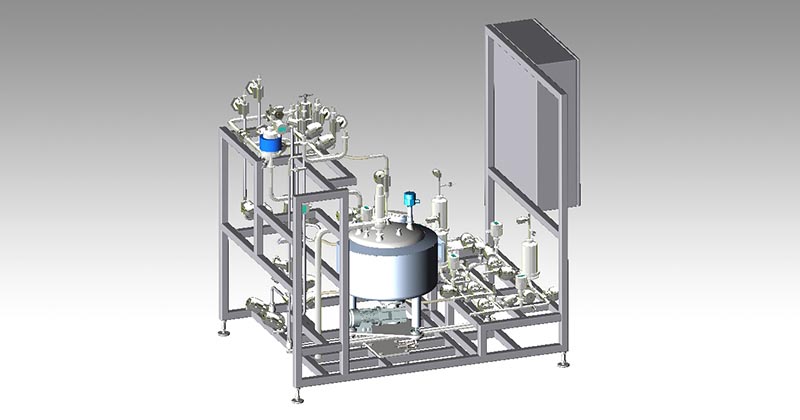

Centec preparation vessels are designed for the production of liquid drugs, infusion solutions, syrups and vaccines.

Description

Highest manufacturing standards, outstanding material quality and extremely precise process control guarantee the most efficient handling of valuable pharmaceutical products. For product preparation, the vessel is first filled with Water for Injection (WFI). Previously weighted raw materials (e. g. concentrates, powders) are then added and dissolved in the water by a circulation pump. For accurate level control, differential pressure meters and load cells are used. To achieve optimum and repeatable product formation, temperature and pressure inside the vessel are controlled within narrow limits. At the outlet of the vessel, the finished product runs through a sterile filter. For Centec preparation vessels a large range of optional equipment is available such as agitators, homogenizers, valves, measurement instruments, and sampling devices. The design of the vessels provides excellent cleaning and sterilization characteristics.

- Vertical or horizontal; single or multi-wall design

- Large range of optional components for high precision process Control

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP/SIP capability

- According to applicable guidelines (e. g. cGMP, FDA, GAMP, ISPE)

- Completely qualified (DQ, IQ, OQ) if desired

Typical Technical Data

| Capacity | 10 – 20.000 l (others on request) |

| Pressure of Operation | – 1 – + 6 bar |

| Temperature of Operation | max. 150 °C |

| Material | 1.4404/1.4435/AISI 316L; etc. |

| Surface Finish | Ra < 0,4 and others possible; electropolishing possible |

| Ferrite Content | < 1 % possible |

| Optionen | measurements of critical parameters such as e. g. pressure, temperature, concentration, pH, O2; insulation; agitator; homogenizer |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl