Application

Water for Injection (WFI) is water required for manufacturing medicines for parenteral administration. The multi effect distillation system DeStill produces sterile, pyrogen-free WFI with the option of combined pure steam generation.

Description

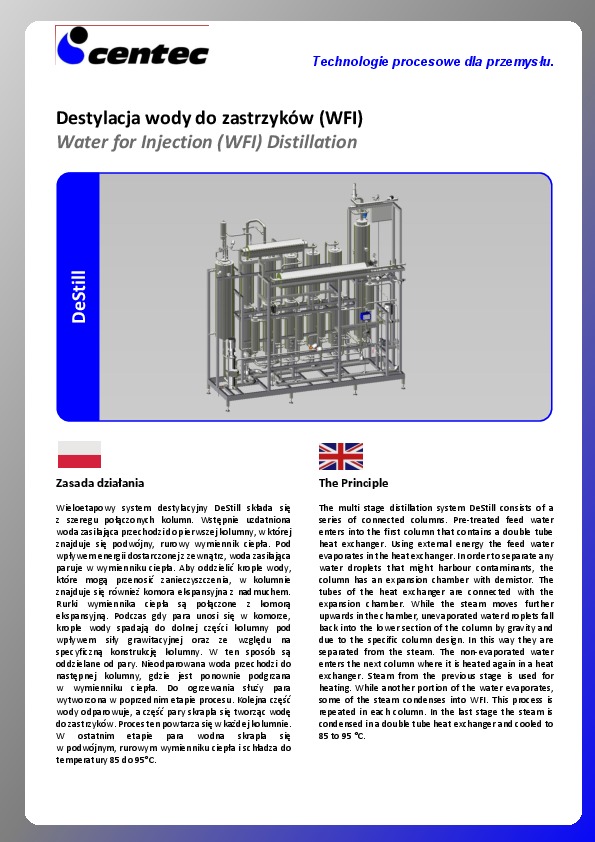

The distillation system consists of a series of interconnected columns and works according to a multistage principle. Pre-treated feed water enters into the first column that contains a double tube heat exchanger. Using external energy the feed water evaporates in the heat exchanger. In order to separate any water droplets that might harbour contaminants like salts and endotoxins, the column has an expansion chamber with demistor. The tubes of the heat exchanger are connected with the expansion chamber. While the steam moves further upwards in the chamber, unevaporated water droplets fall back into the lower section of the column by gravity and due to the specific column design with demistor. In this way they are separated from the steam. The non-evaporated water enters the next column where it is heated again in a heat exchanger. For heating steam from the previous stage is used. While another portion of the water evaporates, some of the steam condenses into WFI. This process is repeated in each column. The more columns, the more energy-efficient the system. In the last stage the steam is condensed in a double tube heat exchanger and cooled to 85 to 95 °C. The concentrated contaminants are directed to drain by a time controlled blow-down valve. As an important quality characteristic, the conductivity of the WFI is continuously monitored. If required, the distillation system can be designed for combined generation of WFI and pure steam at the same time.

- Generation of sterile, pyrogen-free WFI

- Combined WFI and pure steam generation possible

- WFI storage and distribution on demand

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- According to applicable guidelines (e. g. cGMP, FDA, GAMP, ISPE)

- Completely qualified (DQ, IQ, OQ) if desired

Typical Technical Data

| Capacity | 0,1 – 20 m³/h |

| Number of Columns | 4 – 6 (max. 8) |

| WFI Temperature | 80 – 95 °C (lower on request) |

| Bacteria | < 10 CFU/100ml |

| Endotoxins | < 0,25 EU/ml |

| Material | according to requirements (1.4404, 1.4435/AISI 316L, …) |

| Heating Medium | steam, electric heating |

| Cooling Medium | glycol, ice water, brine |

| Options | different automation levels; remote maintenance access; water pre-treatment; combined pure steam generation; WFI storage and distribution (loop) |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl