Application

ALCOHOL MONITOR is a variant of RHOTEC or SONATEC and allows measuring the content of alcohol (ethanol) in a mixture of water and ethanol. The alcohol measurement is done during the production of beer and beer-based mixed drinks.

Description

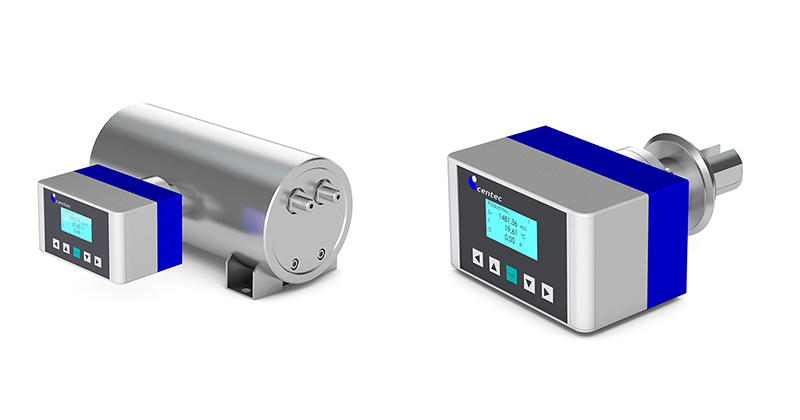

ALCOHOL MONITOR used the functionality of either RHOTEC (density measurement) or SONATEC (sound velocity measurement). The instrument is designed for applications requiring maximum sensitivity and highest accuracy. It is easy to operate and maintenance-free. For density measurement the liquid flows through a thin U-shaped tube inside the sensor. Using electromagnets, the tube is excited to oscillate at the resonant frequency. At the same time, an integrated reference oscillator measures the oscillation characteristics. Even the smallest changes in fluid density have an impact on the detected signal and are identified with highest precision. For sound velocity measurement a sound pulse is created by a piezo-element in a sonic transmitter. It moves perpendicular to the product flow towards a sonic receiver where it is detected. Since the distance between transmitter and receiver is known, the sound velocity can easily be calculated by measuring the travel time of the sonic signal. As a specific property of each liquid, the correlation between concentration and density resp. sound velocity can be described by a mathematical polynomial. With decades of experience and our own laboratory facilities, Centec know the polynomials for a large number of products. Any temperature drifts of the measured signal are automatically compensated for by an internal Pt1000 sensor.

- Most accurate technology to determine alcohol in the manufacturing process

- Patented compact design with local display available

- Hygienic execution and full CIP capability

- Easy to operate and maintenance-free

Technical Data

| Measuring Range RHOTEC | 0 – 100 vol. % |

| Measuring Range SONATEC | 0 – 20 vol. % and 35 – 100 vol. % |

| Accuracy RHOTEC | ± 0,02 vol. % |

| Accuracy SONATEC | ± 0,06 vol. % |

| Response Time | ≤ 1 s |

| Pressure of Operation | max. 16 bar |

| Temperature of Operation | – 25 – + 125 °C |

| Temperature Sensor | Pt1000 |

| Material | 1.4404/1.4435/AISI 316L; Hastelloy; Tantalum; others on request |

| Connections | compatible to Varivent© inline-housings DN40 – DN150; others on request |

| Input Transmitter Version | 6 x digital (24 VDC) |

| Output Transmitter Version | 3 x digital (24 VDC) & 2 x analog (4 – 20 mA) |

| Profibus DP Transmitter Version | option |

| Profibus DP Sensor (w/o local display) | standard |

| Enclosure Rating | IP65 |

| Explosion Protection (ATEX) Ex II 2G EEx d IIC T6 | option |

| Power Supply | 24 VDC |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl