Application

OXYTRANS is a very precise, optical oxygen sensor for measurement of O2 in deaerated water, wort, beer and CO2. Dissolved oxygen has adverse impact on flavour stability and shelf life.

Description

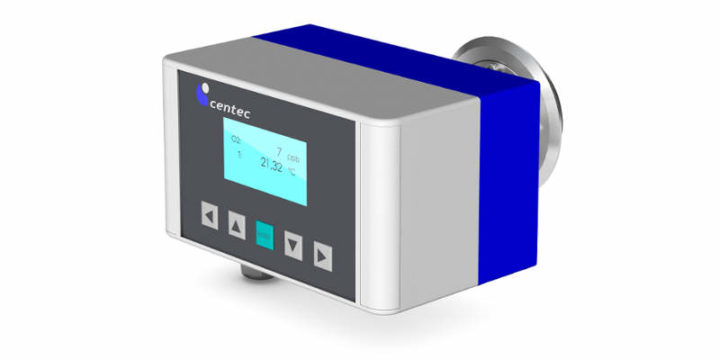

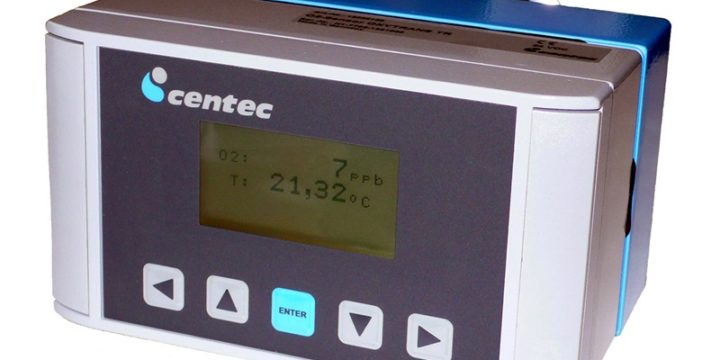

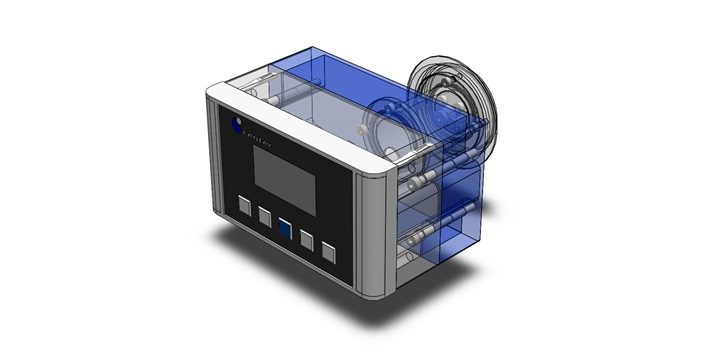

For continuous measurement of dissolved oxygen in liquids and gases, OXYTRANS is perfectly suited. The instrument is designed for applications requiring maximum sensitivity and highest accuracy. It is easy to operate and virtually maintenance-free. Electrolyte solutions are not necessary and no oxygen is consumed during the measurement. The optical measurement technology is based on the effect of luminescence quenching, i. e. the radiationless redistribution of excitation energy via molecular interaction. In the measuring head a small glass component with a thin layer of indicator molecules is installed, the optical window. The indicator molecules are illuminated with blue-green light produced by an LED in the oxygen sensor. They absorb the incident light and are promoted to a higher energy state. After a certain time the molecules convert back to their ground state, during which red light is emitted. The red light is detected inside in the sensor. If O2 molecules are present the energy is transferred from the excited indicator molecules to the oxygen. This molecular interaction causes the excitation energy to be redistributed without any resultant radiation. The detected signal decreases with increasing concentration of oxygen molecules in the product. Other gases don’t absorb this energy, so they have no impact on the measurement result. Any temperature drifts of the measured signal are automatically compensated for by an internal Pt100 sensor.

- Optical technology; no need for electrolyte and membrane changes

- Short response time and excellent long-term stability

- Applicable for a wide range of concentrations and temperatures

- Highly accurate and virtually maintenance-free

- Various flange connections available

- Hygienic execution and full CIP capability

Technical Data

| Liquid Phase Measuring Range | I) 1 ppb – 2 ppm or II) 30 ppb – 35 ppm |

| Liquid Phase Accuracy | I) ± 1 ppb or II) ± 30 ppb |

| Gas Phase Measuring Range | I) 0 – 4,2 % O2 or II) 0 – 50 % O2 |

| Gas Phase Accuracy | I) ± 0,002 % O2 or II) ± 0,03 % O2 |

| Response Time | t90 ≤ 10 s |

| Pressure of Operation | max. 12 bar |

| Temperature of Operation | – 5 – + 55 °C (option: + 98 °C) |

| Temperature Sensor | Pt100 |

| Material | 1.4404/AISI 316L, silicone (FDA), PTFE (FDA) |

| Connections | compatible to Varivent© inline-housings DN40 – DN150; DIN; ANSI; others on request |

| Input | 3 x digital (24 VDC) |

| Output | 3 x digital (24 VDC) & 2 x analog (4 – 20 mA) |

| Profibus DP | option |

| Enclosure Rating | IP65 |

| Power Supply | 24 VDC |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl