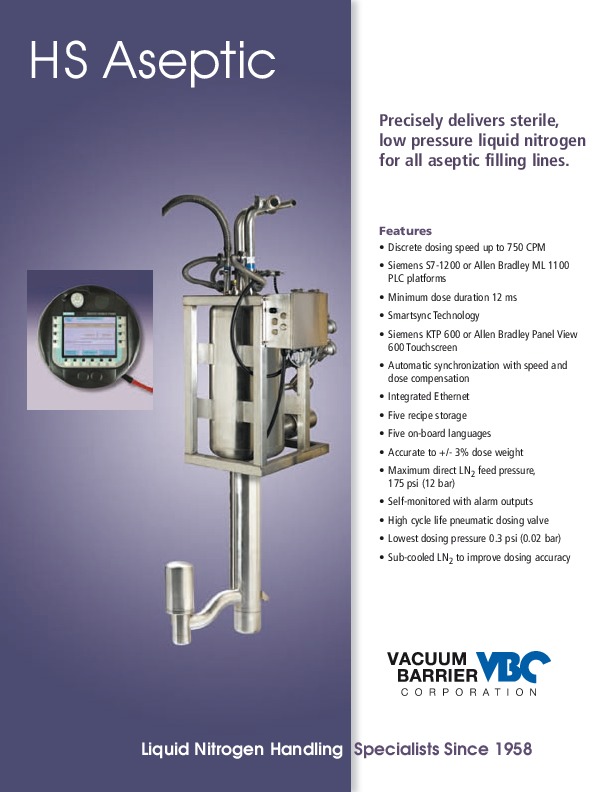

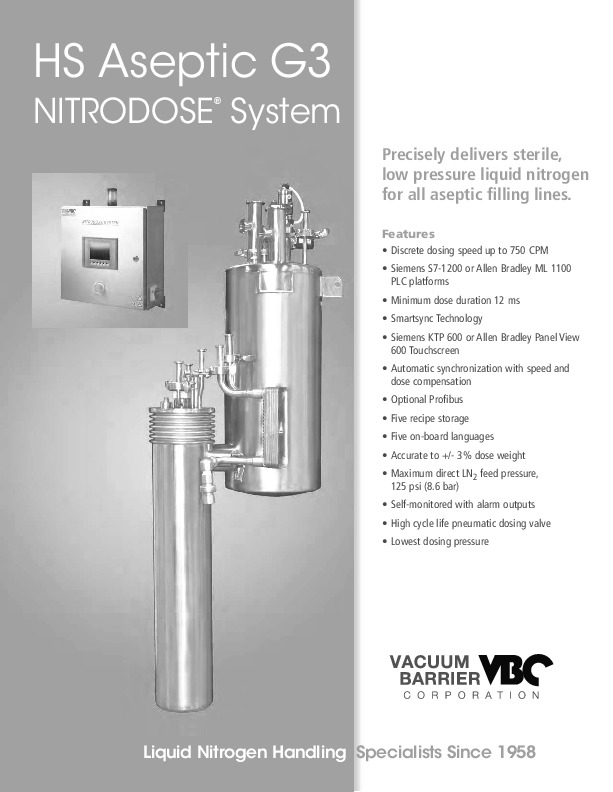

The heat sterilized NITRODOSE® HSA G2 and steam sterilized NITRODOSE® HSA G3, both precisely deliver sterile, low pressure liquid nitrogen for all aseptic filling lines.

- Single phase LN2 dose with an accuracy +/-3% for consistent pressure results

- Discrete dosing up to 750cpm for minimum LN2 consumption

- Lowest delivery pressure available to minimize splashing

Construction

Features

- 316L stainless steel construction

- Fully vacuum jacketed for complete frost free operation

- Equipped with single or redundant 0.2 micron gas filters

- Shiny aseptic

Safety and Cleanliness

- Microbiologically validated by the National Food Lab

- Automated integrity self-checks before and after each sterilization cycle

- Full CE compliant

- Sterile purge gas for protection against frost at nozzle

smooth surface

Controls

Continuously self monitored system with alarm outputs.

- Siemens based PLC controls with touch screen panel for ease of operation

- HSA Siemens handheld

- Ethernet communication capabilities

- Includes encoder option for position based dosing

- On the fly precision dose adjustment

- Dose compensation logic for consistent results over a wide variation of line speeds

- User selectable language accessed thru touch screen menu

- No container/no dose function standard

- Valve cycle counter with automatic notification at service intervals

Options

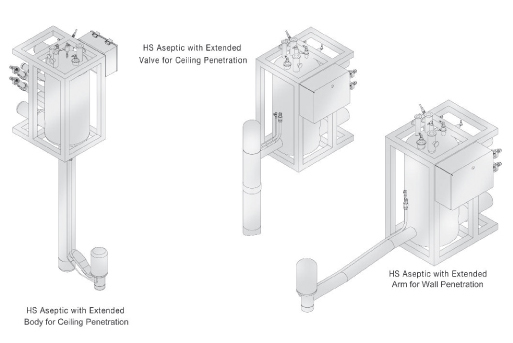

Customer Specified Design

different options customer specified design

Profibus

Communication utility between doser and filler

Encoder

Amount of containers/revolution to be specified.

- 15 m cable

- shaft coupling for 10mm shaft sizes (bracket not included).

Siemens based PLC controls with touch screen panel for ease of operation

HSA control panel with Siemens 1200 plc integrated