Application

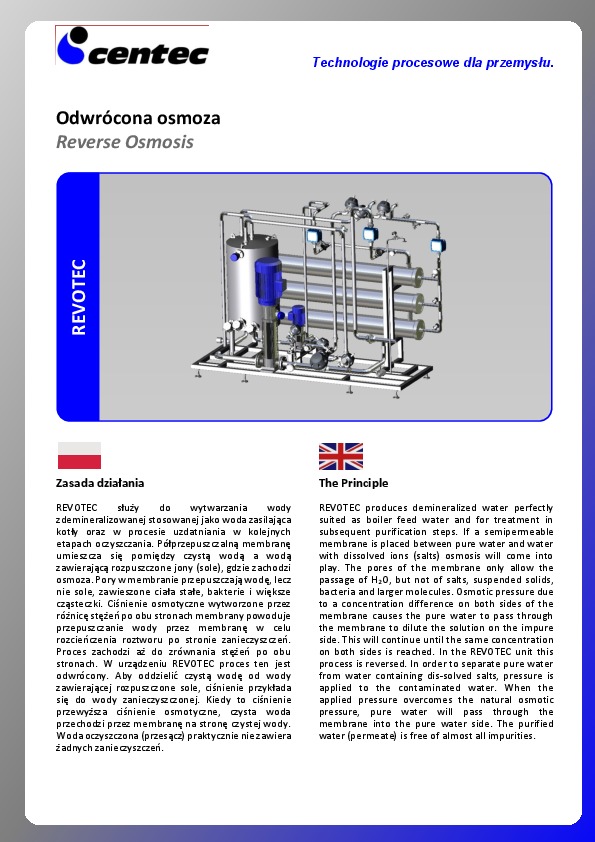

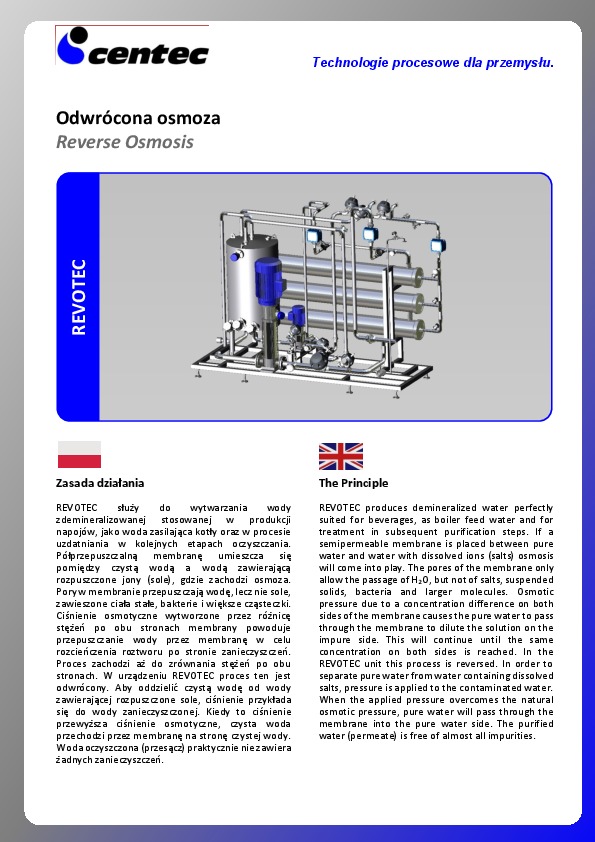

The reverse osmosis system REVOTEC produces demineralized water that is perfectly suited for manufacturing of beer and beer-based mixed drinks. Considering the quality of the raw water, the unit is designed individually for each specific application.

Description

Reverse osmosis (RO) is the reversal of natural osmosis. If a semipermeable membrane is placed between pure water and water with dissolved ions (salts) osmosis will come into play. The pores of the membrane only allow the passage of H2O, but not of salts, suspended solids, bacteria and larger molecules. Osmotic pressure due to a concentration difference on both sides of the membrane causes the pure water to pass through the membrane to dilute the solution on the impure side. This will continue until osmotic equilibrium (the same concentration on both sides) is reached. In the REVOTEC unit this process is reversed. In order to separate pure water from water containing dissolved salts and solids, pressure is applied to the contaminated water. When the applied pressure overcomes the natural osmotic pressure, pure water will pass through the membrane into the pure water side. The purified water (permeate) is practically free of all impurities. This cross-flow technology minimizes fouling of membrane elements by quickly removing the impure water (concentrate). However, depending on the contamination of the raw water, pre-treatment may be required to prevent scaling and chemical attack from oxidizing agents like chlorine. In order to exactly reach the desired water quality and to increase the capacity of the system, permeate can be blended with raw water.

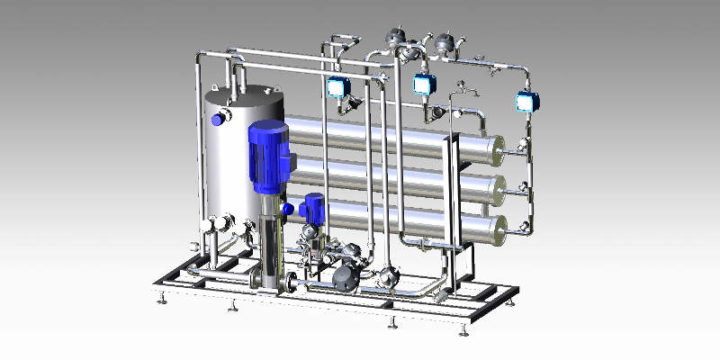

- All stainless steel execution as standard

- Multi-stage system on demand for increased yield

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 – 3.000 hl/h |

| Material | according to requirements (plastics, stainless steel) |

| Options | different automation levels; remote maintenance access; blending of permeat and raw water; conductivity measurement; water pre-treatment/pre-filtration; activated carbon filtration; multi-stage and/or modular design; disinfection; cooling; Cleaning-in-Place |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl