Application

The vacuum deaeration system VeGaS removes oxygen from water, liquid food and dairy products. This improves the flavour stability and extends the product lifetime.

Description

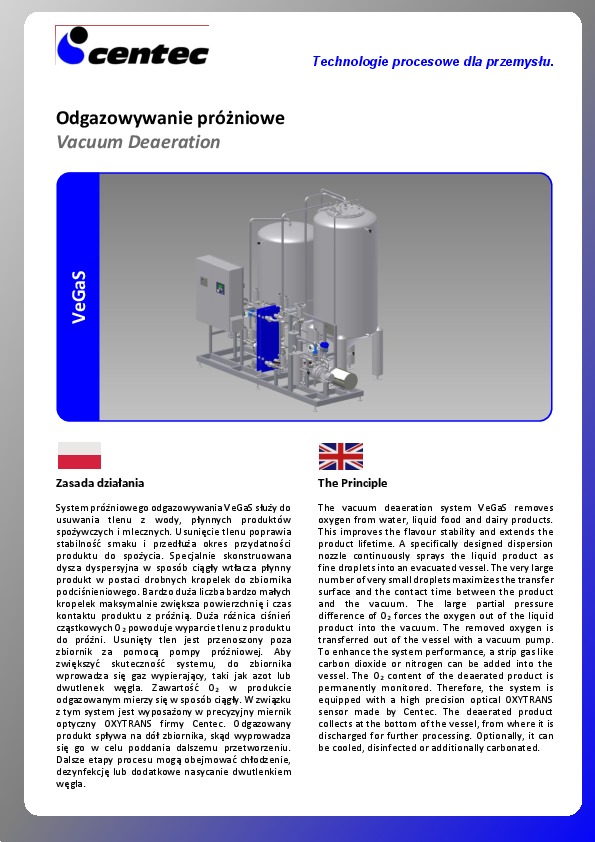

A specifically designed dispersion nozzle continuously sprays the liquid product as fine droplets into an evacuated vessel. The very large number of very small droplets maximizes the transfer surface and the contact time between the product and the vacuum. The large partial pressure difference of O2 forces the oxygen out of the liquid product into the vacuum. This fundamental scientific principle is described by Henry’s Law. The removed oxygen is transferred out of the vessel with a vacuum pump. To enhance the system performance, a strip gas like carbon dioxide or nitrogen can be added into the vessel. The O2content of the deaerated product is permanently monitored. Therefore, the system is equipped with a high precision optical OXYTRANS sensor made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2 control. The deaerated product collects at the bottom of the vessel, from where it is discharged for further processing. Optionally it can be cooled, disinfected with UV light or additionally carbonated.

- High precision OXYTRANS sensor for process control

- Optional carbonation and pasteurization of the product

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 50 – 1.500 hl/h |

| Residual Oxygen | depending on product/application |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line O2/CO2 measurement; strip gas supply; blending/additive dosing; carbonation; pasteurization; cooling |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl