Application

The Unipressure System is used in the beverage industry to accurately measure and control the pressure in one or more tanks. This is an essential requirement for maintaining consistent product quality.

Description

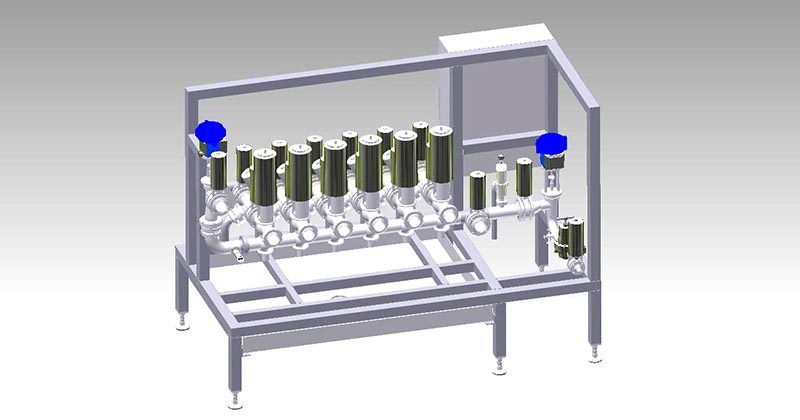

As compact, prefabricated assembly, the Unipressure System requires little space and is quick to install on site, with minimal field welds. It is fully automated and designed to suit each customer’s specific requirements. The system controls the supply of gases and CIP media into the tanks through the tank tops. For sterile applications a sterile gas filter is installed. Double seat valves prevent the intermixing of products and cleaning media. The Unipressure System can be combined with a Centec valve manifold or designed as an independent, compact assembly. Typically, the system is used with storage tanks, fermentation vessels, pressure tanks and deaerated water tanks.

- Applicable for one or more tanks

- Design and manufacture according to specific requirements

- High precision and reliable tank pressure regulation and control

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | according to requirements |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line measurement of critical parameters; double seat valve technology; sterile gas filter |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl