Application

The DeCarbonator is designed for continuous adjustment and especially reduction of the CO2 content of beer and beer-based mixed drinks. A precisely defined and constant CO2 content is an essential quality feature for carbonated beverages.

Description

The system is designed to continuously adjust the CO2 content in a product to the required level. Highly efficient membrane modules allow the CO2 concentration to be increased and decreased with extraordinary accuracy. At the same time the oxygen content is reduced. Each module contains thousands of hydrophobic, gas permeable hollow fibre membranes resulting in a large surface. This large surface maximizes the transfer area and the contact time between product and gas. While CO2 is applied on the inside of the hollow fibres, the product flows in counter current between them on the outside. Depending on the CO2 partial pressure difference between the product and the gas, the CO2permeates through the membranes either out of the membranes into the product or out of the product into the membranes. This fundamental scientific principle is described by “Henry’s Law”. The CO2 content of the carbonated product is permanently monitored. Therefore, the system is equipped with a high precision CARBOTEC sensor made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for CO2 control. Based on this accurate in-line measurement, the carbon dioxide flow is instantly and fully automatically adjusted. The O2 content is measured with proven Centec optical OXYTRANS sensor technology.

- High precision CARBOTEC sensor for process control

- Membrane modules for adjustment and reduction of carbon dioxide content

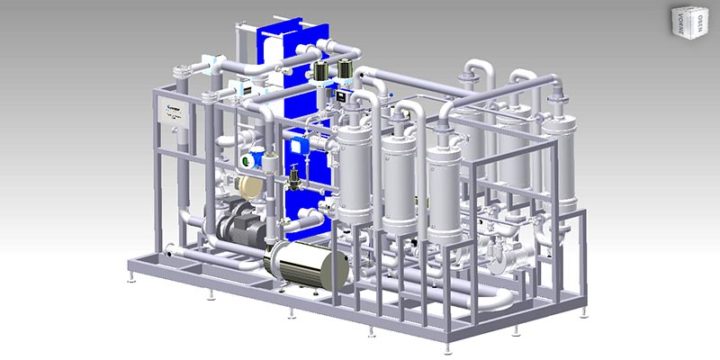

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 2 – 2.000 hl/h |

| Dosing Range CO2 | 0,5 – 10 g/l |

| Dosing Accuracy CO2 | ± 0,1 g/l (on request 0,05 g/l) |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line N2measurement; carbonation; buffer tank; cooling |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl