Application

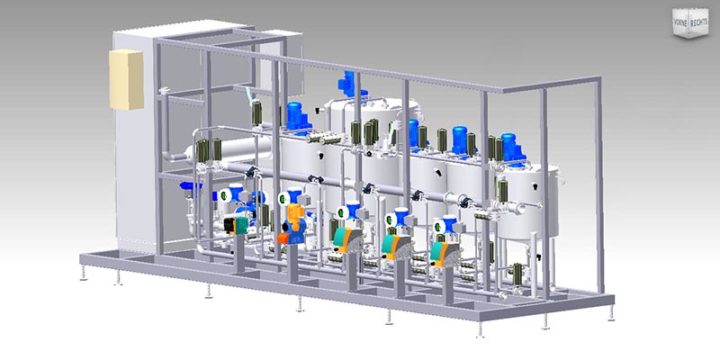

The additive dosing system ADoS is used for dosing of ingredients such as malt extract, hop extract, flavours and colours directly into the main product stream. The compact skid provides a high degree of flexibility for the production of different products (brands).

Description

In additive dosing smaller or larger amounts of ingredients are dosed directly into the main product stream according to a preselected recipe. The number of components can be adapted to meet individual needs. There are various possibilities to supply the additives, e. g. out of separate tanks via supply lines or out of smaller vessels located on the skid. Optionally, the vessels can be heated, purged with CO2 or N2 or equipped with agitators. Reliable flow meters, dosing pumps and pneumatic control valves permanently measure and adjust the quantities. Thus, highly accurate repeatable dosage of even smallest amounts is guaranteed. The modular system design allows for easy expansion, e. g. for mixing with deaerated water, carbonation or pasteurization of the finished product.

- Excellent accuracy for various dosage quantities

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity Main Line | 10 – 1.500 hl/h |

| Capacity Dosage Line | 1 – 5.000 l/h |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line measurement of e. g. alcohol, Brix, CO2; water deaeration; carbonation/nitrogenation; pasteurization; buffer tank; cooling |

Contact:

JMR EUROPE Sp. z o.o.

Sobieskiego 11/204-C

40-084 Katowice

Tel: +48 (32) 352 04 24

Kom: +48 601 424 429

E-mail: jmr@ceti.pl