The correct planning of service intervals, the regular performance of inspections and the ability to anticipate and plan post-service activities make it possible to avoid unexpected interruptions in the production process and extend the life of your SIGMA plate heat exchanger.

Together with you we will create an individual, “tailored” service concept for your SIGMA. The scope of our service program includes:

• Free telephone service (24 hours)

• Coordination of the on-site service

• Cost estimate for service repairs

• Original spare parts offer

• Stationary repair of exchangers, plate packs as well as individual exchangers

• Collective settlement of services

The scope of maintenance and inspection includes:

• Checking through bolts for tightening

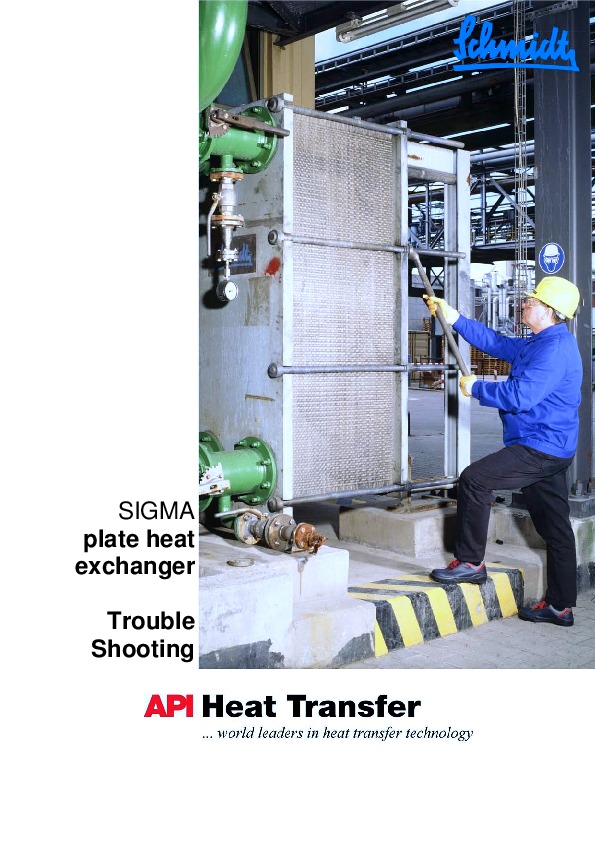

• Opening the plate heat exchanger

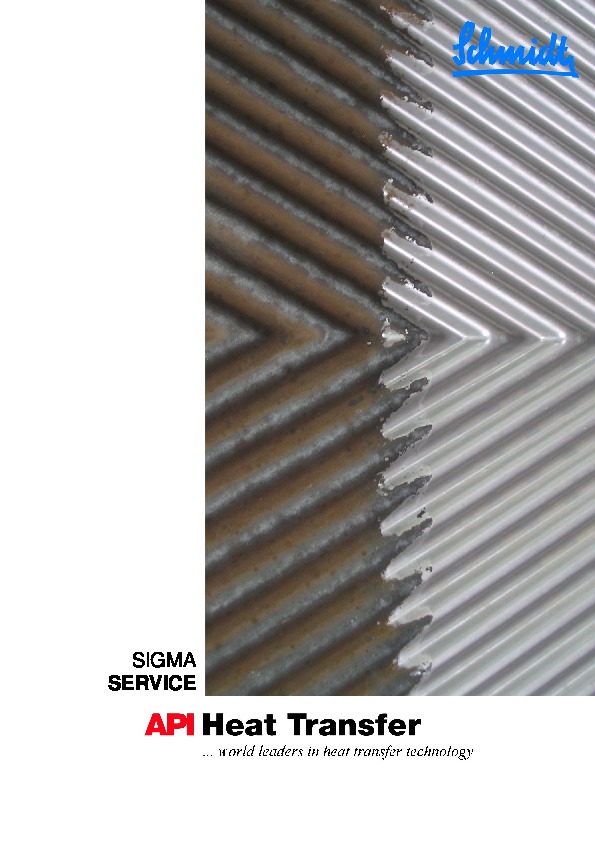

• Checking degree of contamination

• Checking the plate pack, if necessary, investigating cracks where they may occur

• Checking condition of gaskets

• Checking frame components

• Carrying out the repair (cleaning, replacement of gaskets, major repair, assembly of panels in our service hall or at the customer’s premises)

• Reconstruction and connection of the plate heat exchanger and installation of the unit according to the connection diagram

• Adjusting the tightening of the through bolts to achieve proper sealing

• Checking the tightness during operation, pressure test

• Preparing the inspection report